- Improved design obsoletes moving canisters and minimizes moving parts.

- Continuous batch drying process.

- -40° dew point air is constantly bled into vacuum and retention hoppers.

- Vertical design minimizes footprint.

- No heat loss is guaranteed with 4″ double-insulation on all vessels.

- Reduced Maintenance – no desiccant to change – no filters to clean.

- Faster drying improves production planning.

- “No stress” material drying – means no material degradation.

- Process temperatures up to 350°F. (175°C)

- Vacuum take-off or gravity feed material discharge available.

- Backed by same 5-year warranty as all Maguire products.

|

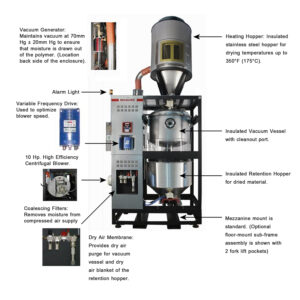

| VBD-1000 installed on mezzanine |

| How the VBD-1000 Dryer Works:

VBD Vacuum Dryers utilize a 3-stage continuous batch drying process |

|

|

Stage 1: Material in the heating hopper is brought to set point by means of a centrifugal blower through a 40 Kw heating element. The requested heating temperature is adjusted on the control panel and the cycle lasts 45 minutes (60 minutes for PET). Stage 2: Upon reaching the desired set point, heated material is discharged from the heating hopper into the vacuum vessel. The vacuum is brought to 75mm Hg absolute pressure and held to a 20mm Hg differential for the set cycle time. The vacuum cycle typically lasts for about 20 minutes so you have ready-to-process material in 65 – 80 minutes.

Stage 3: The dried material is discharged into an insulated retention / take-off hopper for consumption. A positive pressure heated dry air purge is maintained on the material.

|

|

VBD Controller

Simple is better – no confusing icons – only two screens to monitor

The controller is a Motorola micro-processor

- Four buttons provide access for setting operation mode, adjusting dryer parameters and many additional program functions.

- Alarms are shown on the display and signaled by an alarm light and horn with silence function.

- Reports can be generated via a USB port to either a memory stick or printer.

- Program updates via flash memory using a standard USB memory device.

| Energy usage comparison with dual-desiccant bed dryer | ||

| Dual Bed Dryer vs. Maguire VBD-1000 Vacuum Dryer | ||

| Drying 1000 lb/hr (454 kg/hour) of nylon at 170°F ( 77°C): – Electrical consumption only – Compressed air generation electrical requirement for 9.8 SCFM TOTAL True Energy Consumption @ 170°F (77°C) |

Dual Bed watts/Kg/hr 81.8 81.8 |

VBD watts/Kg/hr 30.8 8.1 38.9 |

| VBD ENERGY SAVINGS 53% | ||

| Drying 1000 lb/hr (454 kg/hour) of Polycarbonate at 250°F ( 121°C): Dual Bed VBD |

||

| Total True Energy Consumption @ 250°F (121°C) | 120.3 | 53.4 |

| VBD ENERGY SAVINGS 56% | ||

|

Note: “compressed air generation electrical requirement” is the amount |

||

|

|

|||||||||||||||||||||||||||||||||||||||

There are no reviews yet.