WXB Blender for Extrusion

Integrated Blending & Extrusion Control

- Maguire’s proven WXB Gravimetric batch blending technology combined with comprehensive loss-in-weight control.

- Batch blending from 2 – 12 materials with dispense accuracy of +/- 0.1% on a 1% setting.

- Integrated Loss-in-Weight control monitoring live consumption rate to an extruder and updating process rate every second.

Maguire + Syncro Syntrol Control

- Maguire + Syncro specialist extrusion control for every type of extrusion process.

- Syntrol touchscreen allows quick and easy setup of extrusion process.

- Easily set process parameters like gram/meter, micron and layer ratios.

Key Benefits of Extrusion Control

- Overall raw materials savings of up to 10% compared to manual regulation.

- Reduced start-up material wastage & changeover scrap.

- Achieve faster startup times.

- Automatically regulate extruder and haul-off speeds to always be on target.

- Eliminate process variations due to screen pack, voltage fluctuations and MFI differences.

- Document clearly materials usage and process parameters for quality, process and cost control.

- Return on investment within 6 months.

- Fast payback by reduced material usage, production scrap, manual intervention and increased productivity.

- Optimize process from constant extrusion control.

See the WXB in Operation

What makes the WXB blender uniquely positioned for all extrusion processes?

Watch and learn more:

- See typical installations.

- See quick and easy setup.

- See how the WXB compares to the WSB Blender.

- See how you can gain return on investment within 6 months.

- Top 5 benefits of Maguire WXB Extrusion Blenders.

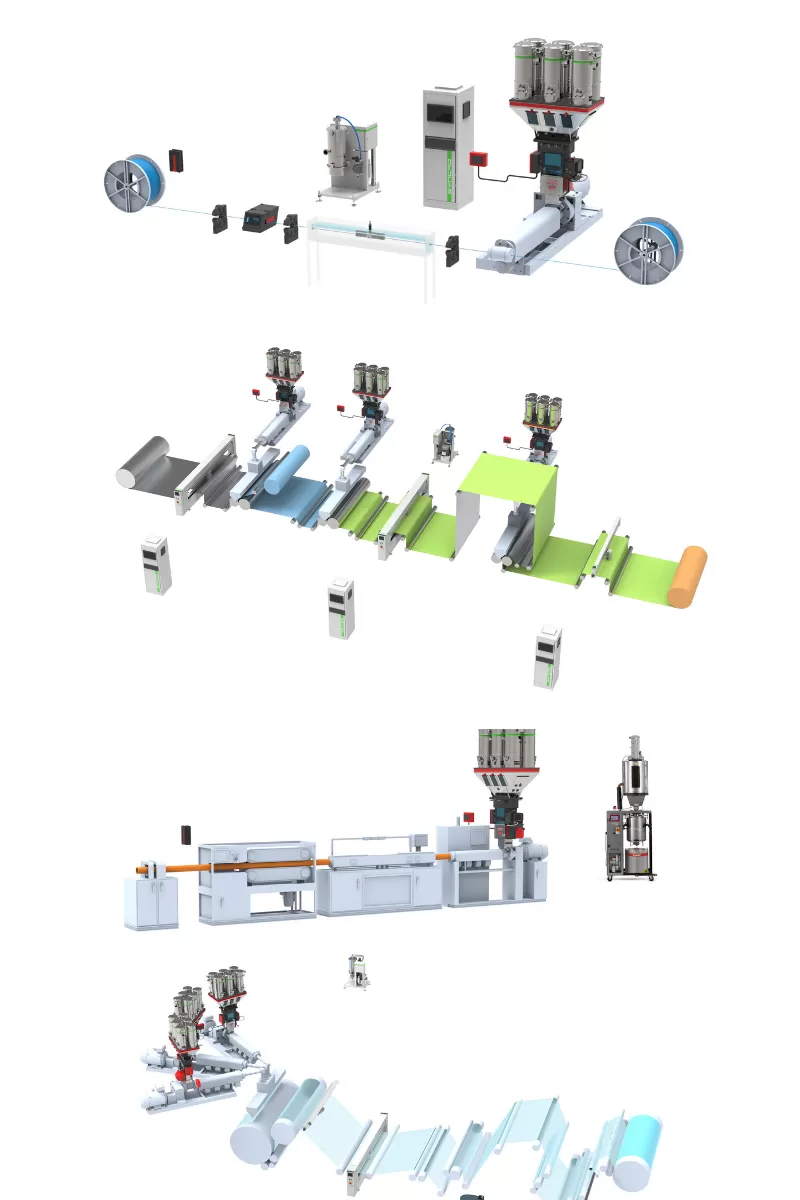

Solutions for Every Extrusion Process

Solutions for Extrusion Processes

- Suited to continuous extrusion processes for mono and co-extrusion processes.

- Applications include cable, cast film, blown film, sheet, pipe, tube & profile extrusion.

Maguire+Syncro Control Flexibility

- Detailed control of all materials settings, layer ratio control, & extrusion control.

- Controller allows effective control for mono and co-ex processes, managed from 1 HMI.

Expandable & Modular

- The WXB control is expandable and can be simply integrated with further downstream controls for automatic gauging and process control.

- WXB extrusion control module can easily be retrofitted with other modular components from Maguire + Syncro including air rings, IBC control, Gauging, and in-line recycling.

WXB Blender at a Glance

1. Integrated Loss-in-Weight

The WXB mix chamber is a combined Loss-in Weight hopper which provides live lb/hr (kg/hr) data updated every second.

3. Up to 10% Material Cost Reduction

Up to 10% material cost reduction from automatic gram/meter / micron regulation, quicker start-up and reduced start-up material scrap.

5. Modular Upgrades

Control integrates to allow modular upgrades for air rings, IBC, gauging and a wide range of downstream controls to optimize multiple extrusion processes.

2. Gravimetric Batch Blending

Precise, reliable dosing control for 2 – 12 raw materials, providing material control for every extrusion process.

4. Control Extrusion

Immediate responsive control from setpoint to actual, maximizing on materials formulations, minimizing on material cost.

6. Co-Ex Layer Control

Easily set, monitor and adjust layer ratios and easily manage multi-layer applications.

Extrusion Control Configurations

| Option | Description | |

| OPXS-W-M | M+S Extrusion Control for WSB or WXB Gravimetric Blender – Main box with PLC I/O, without HMI touchscreen. Control interface to #1 Extruder + #1 Haul Off. OPXS-HMI-**-OEM required for user interface. |

|

| OPXS-W-S | M+S Extrusion Control for WSB or WXB Gravimetric Blender – Secondary box with PLC I/O, no HMI touchscreen, Control interface to #1 Extruder. | |

| OPXS-W-M-07 | M+S Extrusion Control for WSB or WXB Gravimetric Blender – Main box with PLC I/O,with 7″ HMI touchscreen. Control interface to #1 Extruder + #1 Haul Off. |  |

| OPXS-W-M-10 | M+S Extrusion Control for WSB or WXB Gravimetric Blender – Main box with PLC I/O, with 10″ HMI touchscreen. Control interface to #1 Extruder + #1 Haul Off. | |

| OPXS-HMI-07-OEM | M+S Extrusion Control – 7″ HMI Touchscreen Panel – to position remotely in OEM cabinet. |  |

| OPXS-HMI-10-OEM | M+S Extrusion Control – 10″ HMI Touchscreen Panel – to position remotely in OEM cabinet. | |

| OPXS-LINEKIT | M+S Extrusion Control – #1 Metric Wheel with Encoder, + #1 Installation Bracket, +100ft (30m) Cable. |

|

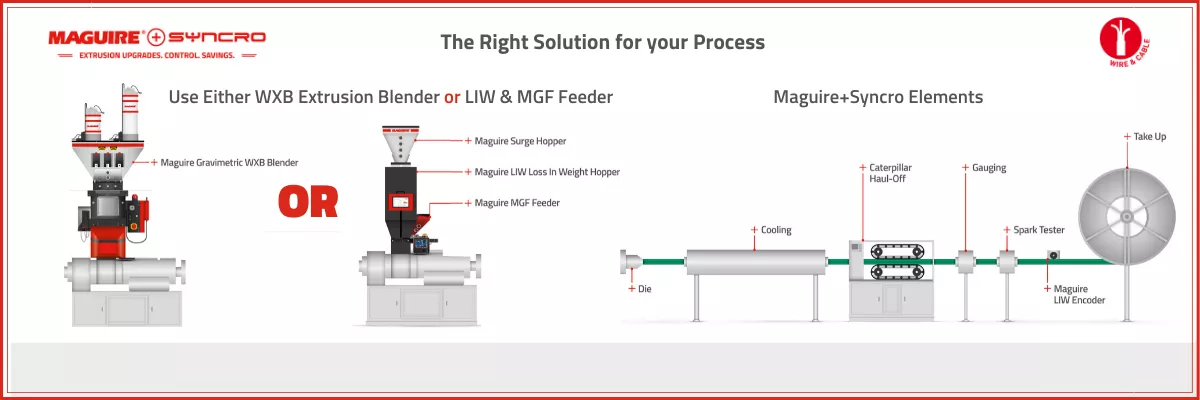

WXB Blender vs. LIW & MGF

Using a WXB Blender compared with a WSB Blender and Maguire Surge Hopper, LIW Loss in Weight provides multiple benefits.

- Save space.

- Faster material changes.

- Faster start up – scrap reduction.

- Precise, reliable dosing control for 2 – 12 raw materials.

- Easily set, monitor and adjust layer ratios and easily manage multi-layer applications.

- Full system control flexibility, all from 1 screen.

There are no reviews yet.