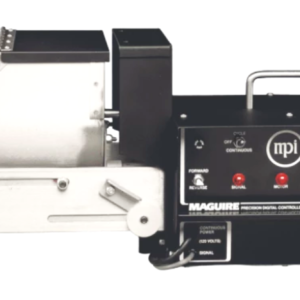

Compact Construction

Removable Stainless Steel Hopper

- 0.5 cubic foot (14 L) hopper holds up to 30 pounds (13.5 kg).

- 4 sight glasses for easy view of color level.

Simple Installation & Access

- Mounted directly over feed throat of machine for easy access.

- Feeder motor positioned on one side, hopper on the other side to evenly balance the weight of the feeder over the feed throat of the machine.

- Remote control configuration further reduces weight of the equipment.

See-Through Baffle Chamber

- Stainless steel baffle ensures even masterbatch distribution.

- Removable acrylic windows provide clear view of resin and color flow.

- Allows easy access to baffle chamber.

5 Year Warranty

- Backed with 5 Year Warranty.

Simple Operation

Simple Setup Procedure

- Enter the percentage setting.

- Then either the molding shot weight or extrusion throughput.

- The MLG Feeder automatically doses, metering color evenly into the process machine.

Easy Cleanout and Material Changes

- Easy removal of hopper, auger and auger tube.

- No tools required, no pellets cross contamination.

MLG Feeder at a Glance

1. Simple Setup Procedure

Simply enter the percentage setting, then either the molding shot weight or extrusion throughput and the MLG Feeder will automatically start dosing, metering color evenly into the process machine.

3. Simple Installation

Mount feeder directly over throat of machine – offering easy access during production.

2. Ease of Use

Removable acrylic windows provide clear view of resin and color flow, as well as easy access to the baffle chamber.

4. Quick Cleanout

Easy removal of hopper, auger and auger tube. No tools required.

MLG Feeder Specification

| Model | Auger Size | Max RPMs | Continuous Output lb/hr | |

| Min | Max | |||

| MLG-4-18 | 1/2″ (12mm) | 30 | 0.05 (0.02 kg) | 4 (1.8 kg) |

| MLG-4-34 | 1/2″ (12mm) | 55 | 0.1 (0.05 kg) | 7 (3.2 kg) |

MLG Feeder Options

| Option | Model | Description | |

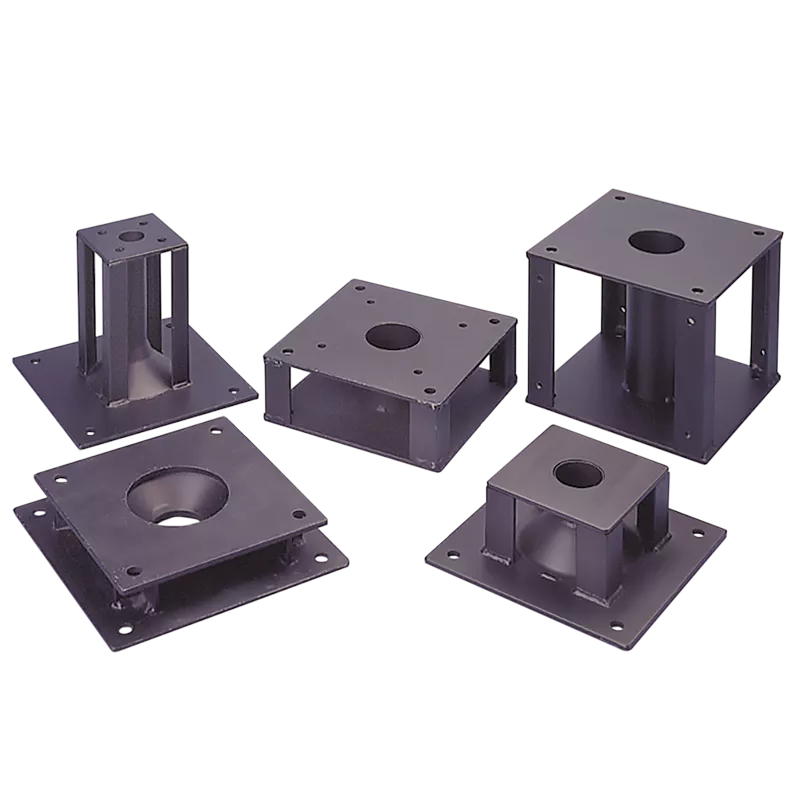

| Spacer Frames | MLG-4-18, MLG-4-34 | Raise feeders above the feed throat of the process machine. To improve access & material change over times |  |

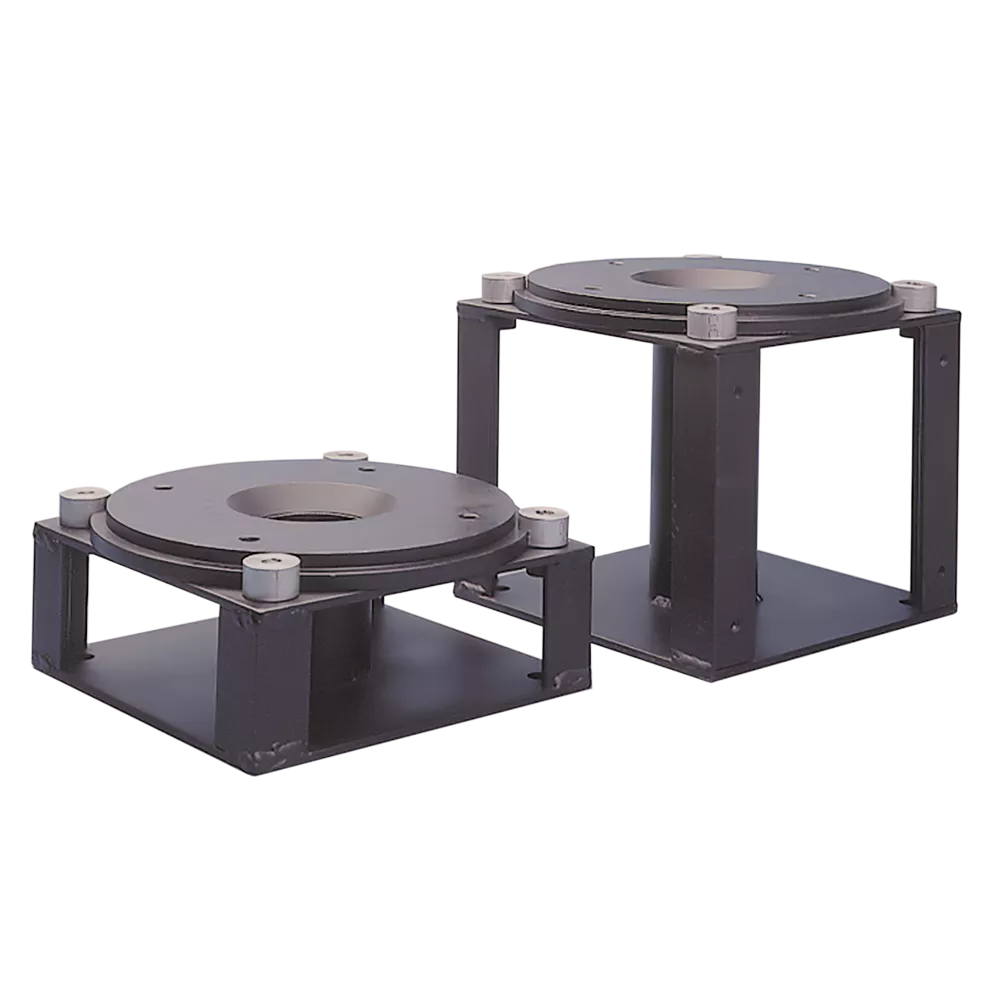

| Swivel Plates | MLG-4-18, MLG-4-34 | Allow for easy re-positioning of auger feeder & full rotation of the feeder to any position required |  |

| Hopper Extensions | MLG-4-18, MLG-4-34 | Range of hopper extension sizes for different models to increase storage capacity |  |

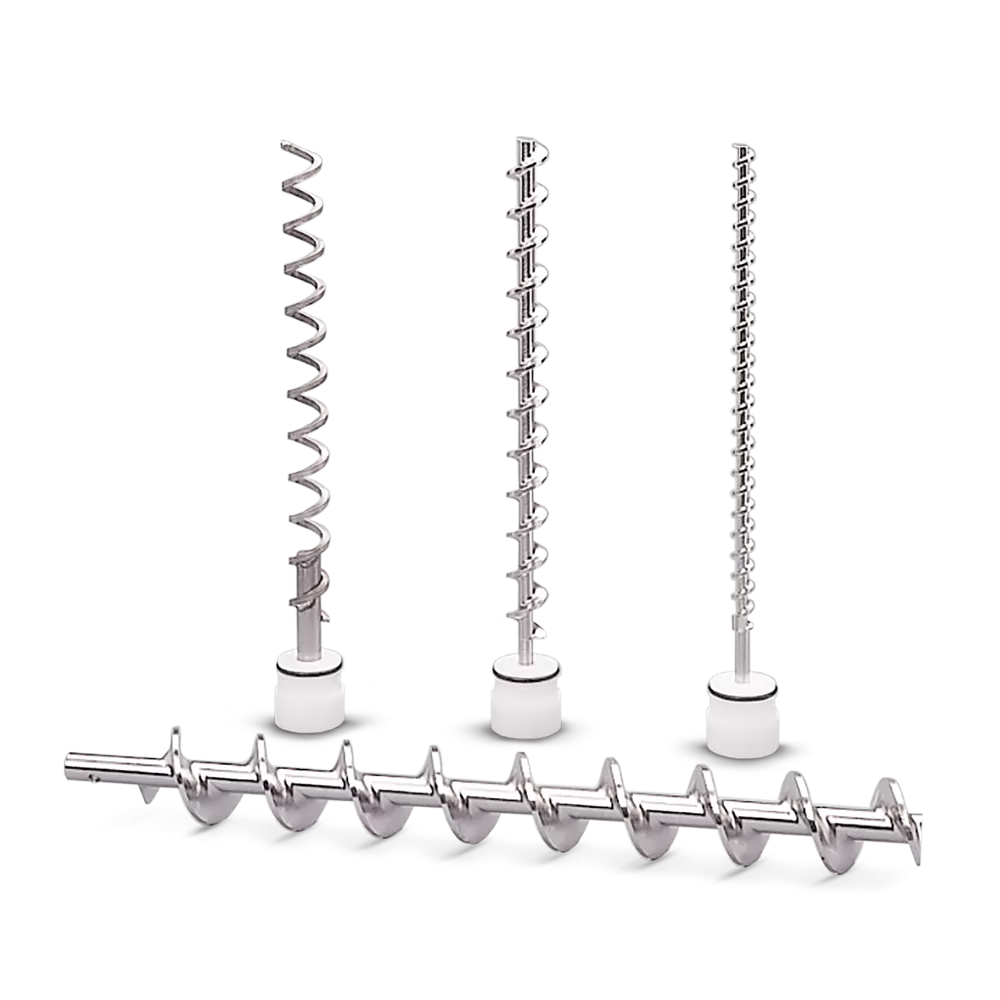

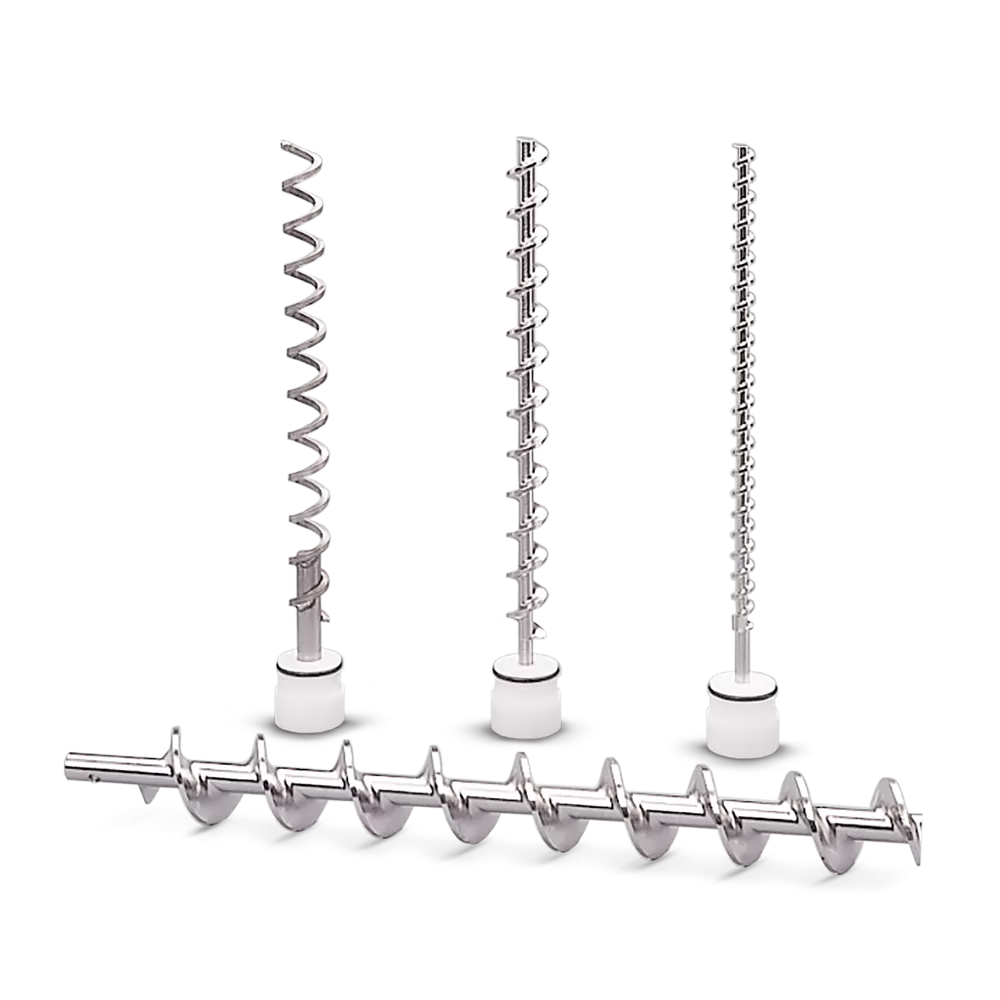

| Powder Feeder Augers | MLG-4-18, MLG-4-34 | 1 1/2″ and 1″ augers for feeding free flowing additive powders |  |

| Clear-Vu Surge Hoppers | MLG-4-18, MLG-4-34 | To easily view material status before material is entering the material line |  |

| Spare Controllers | MLG-4-18, MLG-4-34 | Spare automatic speed controller. Also available with Extrusion Following for extrusion applications. |  |

| Augers with Couplings | MLG-4-18, MLG-4-34 | Augers with 1/2″, 1″ and 2″ coupling. |  |

| Auger Tubes | MLG-4-18, MLG-4-34 | 1/2″, 1″, and 2″ auger tubes are available. |  |

| Low Level Alarm | MLG-4-18, MLG-4-34 | Reduce monitoring requirements by floor personnel with the LLA alarm system, used to signal HGH or LDW material-supply conditions. |  |

There are no reviews yet.