Loss-in-Weight Hopper for Extrusion

Loss in Weight Control

- Comprehensive loss-in-weight control, monitoring live consumption rate to an extruder and updating process rate every second.

- The LIW hopper is suspended on a pair of highly accurate load cells.

- Sized according to throughput.

- Throughput of line is fully automatic and requires no user intervention.

Maguire + Syncro Syntrol Control

- Maguire + Syncro specialist extrusion control for every type of extrusion process.

- Syntrol touchscreen allows quick and easy setup of extrusion process.

- Easily set process parameters like gram/meter, micron and layer ratios.

Key Benefits of Extrusion Control

- Overall raw material savings of up to 10% compared to manual regulation.

- Reduced start-up material wastage & changeover scrap.

- Achieve faster startup times.

- Automatically regulate extruder and haul-off speeds to always be on target.

- Eliminate process variations due to screen pack, voltage fluctuations and MFI differences.

- Document clearly material usage and process parameters for quality, process and cost control.

- Return on investment within 6 months.

- Fast payback by reduced material usage, production scrap, manual intervention and increased productivity.

- Optimize process from constant extrusion control.

Simple Operation

Range of Material

- Suited to every application of free-flowing material, pellets, granules or powder.

Rapid Access

- Magnetic retainers on the hopper enclosure allow quick access to the LIW hopper.

Audible and Visual Alarms

- Alarms are activated is system is not operating withing required process conditions.

Faster-Start up Time

- Switch from manual start-up to automatic and set required output.

- No further operator involvement.

Quick Material Release

- Optional compact drain can be mounted directly below the LIW hopper.

- Rapid draining of materials.

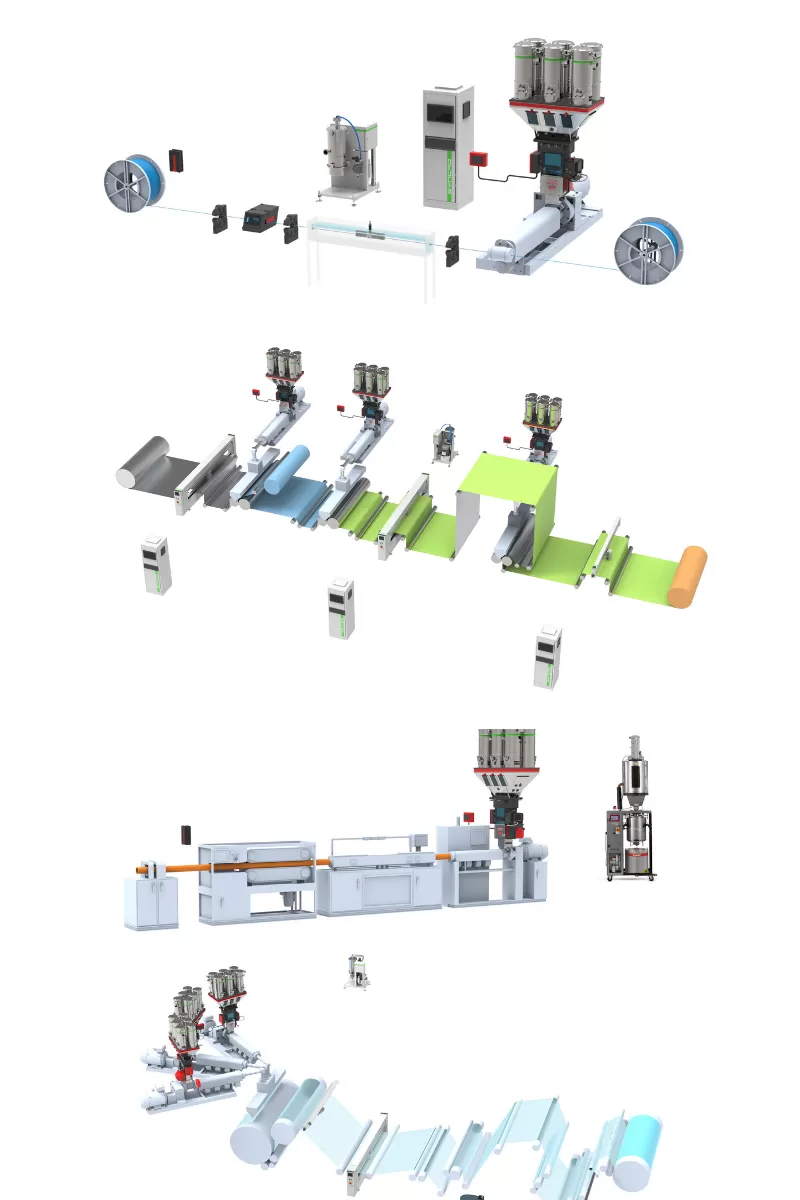

Solutions for Extrusion Processes

Solutions for Extrusion Processes

- Suited to all continuous extrusion processes for mono and co-extrusion processes.

- Applications include cable, cast film, blown film, sheet, pipe, tube & profile extrusion.

Maguire+Syncro Control Flexibility

- Detailed control of all material settings, layer ratio control, & extrusion control.

- Controller allows effective control for mono and co-ex processes, managed from 1 HMI.

Expandable & Modular

- The LIW control is expandable and can be simply integrated with further downstream controls for automatic gauging and process control

- LIW Hopper extrusion control module can easily be retrofitted with other modular components from Maguire + Syncro including air rings, IBC control, Gauging, and in-line recycling.

Adding Masterbatch and Additives

Options for incorporating MGF Gravimetric Feeder into Maguire + Syncro control for accurate dosing of masterbatch and additive.

- The Maguire MGF series can be used for all extrusion applications.

- Fit easy, cost effective control for an additive or masterbatch.

- Plugs in and controls directly from Maguire +Syncro control box.

- Feeder automatically re-calibrates to new color, so no additional setup required.

- Feeder automatically doses according to extrusion throughput reference entered into control.

- MGF follows complete process data from LIW live. Loss in weight updates process consumption every second.

Loss in Weight Control at a Glance

1. Suited to all Extrusion Processes

The LineMaster Loss-in-Weight control is suited to all continuous extrusion processes, for both mono and co-extrusion processes.

3. Reduced Scrap

Savings from reduced start-up material waste and changeover scrap.

5. Continuous Accuracy

The LIW Hopper is suspended on a pair of highly accurate load cells, sized according to throughput.

2. Savings up to 10% of Materials Cost

Switching from manual regulation to automatic extrusion control allows significant savings.

4. Immediate Control

Immediate control by responding to actual material consumption versus target required, offering rapid return on investment.

6. Maguire + Syncro Control Flexibility

Maguire + Syncro extrusion control solutions allow operators to manage material settings, consumption, layer ratio control and recipe storage.

Maguire+Syncro Control Options

| Option | Description | |

| OPXS-LIW-M | M+S Extrusion Control for LIW Loss-in-Weight hopper & MGF Feeder – Main box with PLC I/O, without HMI touchscreen. Control interface to #1 Extruder + #1 Haul Off, OPXS-HMI-**-OEM required for user interface. |

|

| OPXS-LIW-S | M+S Extrusion Control for LIW Loss-in-Weight hopper & MGF Feeder – Secondary box with PLC I/O, no HMI touchscreen, Control interface to #1 Extruder. | |

| OPXS-LIW-M-07 | M+S Extrusion Control for LIW Loss-in-Weight & MGF Feeder – Main box with PLC I/O, with 7″ HMI touchscreen. Control interface to #1 Extruder + 1# Haul Off. |  |

| OPXS-LIW-M-10 | M+S Extrusion Control for LIW Loss-in-Weight & MGF Feeder – Main box with PLC I/O, with 10″ HMI touchscreen. Control interface to #1 Extruder + #1 Haul Off. | |

| OPXS-HMI-07-OEM | M+S Extrusion Control – 7″ HMI Touchscreen Panel – to position remotely in OEM cabinet. |  |

| OPXS-HMI-10-OEM | M+S Extrusion Control – 10″ HMI Touchscreen Panel – to position remotely in OEM cabinet. | |

| OPXS-LINEKIT | M+S Extrusion Control – #1 Metric Wheel with Encoder, + #1 Installation Bracket, +100ft (30m) Cable. |  |

LIW Options

| Option | Model | Description | |

| Surge Hopper | LIW-05W, LIW-10W, LIW-25W, LIW-40W | Quick filling of LIW hopper for fast process turnaround |  |

| Drain Ports | LIW-05W, LIW-10W, LIW-25W, LIW-40W | Mounted below the LIW hopper for quick material evacuation and simple cleaing and material changes |  |

| MSF Starve Feeders | LIW-05W, LIW-10W, LIW-25W, LIW-40W | Regulates the weight per hour of material supplied to ther line. Prevents the twin-screw extruder from being flooded with material |  |

| FMC Flow Moderator Cones | LIW-05W, LIW-10W, LIW-25W, LIW-40W | For use with free-flowing powders such as PVC. Ensures consistent flow from LIW hopper into extruder |  |

There are no reviews yet.