Blenders Built to Perform

Robust Construction

- 30+ years of experience in Gravimetric Blending.

- Robust hardware integrated with industry leading software control.

- Consistent accuracy that is simple and easy to use.

5 Year Warranty

- Industry leading, comprehensive 5 Year Warranty.

- Warranty as robust as the blender system.

Simple Operation

Maguire Blenders operate in 3 simple steps:

- Load material hoppers with regrind, natural, color and additive.

- Set the recipe percentage for each material.

- Blend batch by batch direct to your process.

Simple Material Changes and Maintenance

- Easy access to all material contact surfaces – including hoppers, weigh bin and mix chamber.

- System operates with minimal maintenance – no tools required.

Install Where You Like

Maguire Blenders can universally be installed however best for a process, including:

- Blender mounted on throat for optimum mix control, maximum use of space, easy access.

- Blender mounted on floor stand for easy access beside the machine, simple material changes.

- Blender mounted on Mezzanine floor for easy access above the machine.

How Maguire Blenders Work:Easily Change Material on Maguire Blenders:Install Maguire Blenders Anywhere:

Buy Maguire Experience

Maguire revolutionized gravimetric blending when it launched the first Maguire Batch Blender in 1989.

The evolution and development of the Maguire blender has been constant throughout 30+ years, based on customer feedback and continuous research and development – with over 200+ patents and counting.

The Maguire Control Logic

Each blender is equipped with blender software to provide solutions for every type of processing challenge. When you buy a Maguire, you buy experience.

- Close to 60,000 units operating across thousands of applications and industries.

- All controls are interchangeable and backward compatible.

- Multiple features and functions as standard, providing the most flexible dosing and blending control in the industry.

Latest Generation Blender Control – 4088 Touchscreen

- FlexBus Lite full feature conveying control.

- Maguire’s latest 4088 controller is fully backward compatible.

- More features and functions built into software as standard.

- Maguire OS updates with latest features and functions.

- Intuitive graphics, intuitive to use.

- Fast and simple to swap out in the event of service and support.

- Powerful microprocessor control – fast and responsive user experience.

Integrated Conveying Control:

Steve’s View on Accuracy

When adding color to your process, today as in the past, processors focus on product quality and cost. Accuracy was, and still is, the key to achieving these objectives. Not just accuracy when first set up, but continuous accuracy over the entire production run.

Since our introduction of the first reasonably priced gravimetric blender in 1989, the product we gave the name “Weigh Scale Blender”, gravimetric has virtually replaced volumetric blending for one simple reason; gravimetric assures that we maintain these two objectives, hour after hour, day after day, without operator intervention or frequent monitoring and correction.

In the past, over coloring was the norm. Today, blending by weight has solved that problem.

Today no one questions that Gravimetric is better then Volumetric. Instead, ads now often make sales claims about their blenders high level of “accuracy”. This paper about accuracy, which Steve Maguire wrote over 25 years ago, still remains true today. There is still no standard way to measure “accuracy”.

Claims continue about accuracy based on “percentage” values, but seldom is there supporting data or explanation of what their number means. We are left to guess at the meaning.

Steve Maguire in 1990 with the launch of the WSB 140R This paper explains what they may, or may not, be saying. Then you can decide what accuracy means.

Download Steve’s explanation here.

Improve Quality and Reduce Cost

Accuracy to ± 0.1% on a 1% Setting

- Repeatable consistent dosing accuracy – 1/10 percent of requested target.

- Dosing dynamically adjusts as densities / flow rates change.

Load Cells

- Load cell resolution is 1/40 of a gram (about 1 pellet) – the addition of just 1 pellet will cause the reading output to increment by 1.

- Over an extended time period the system is extremely accurate.

- Each batch followed by an error correct routine – assuring the next batch “learns” from any significant error that may have occurred.

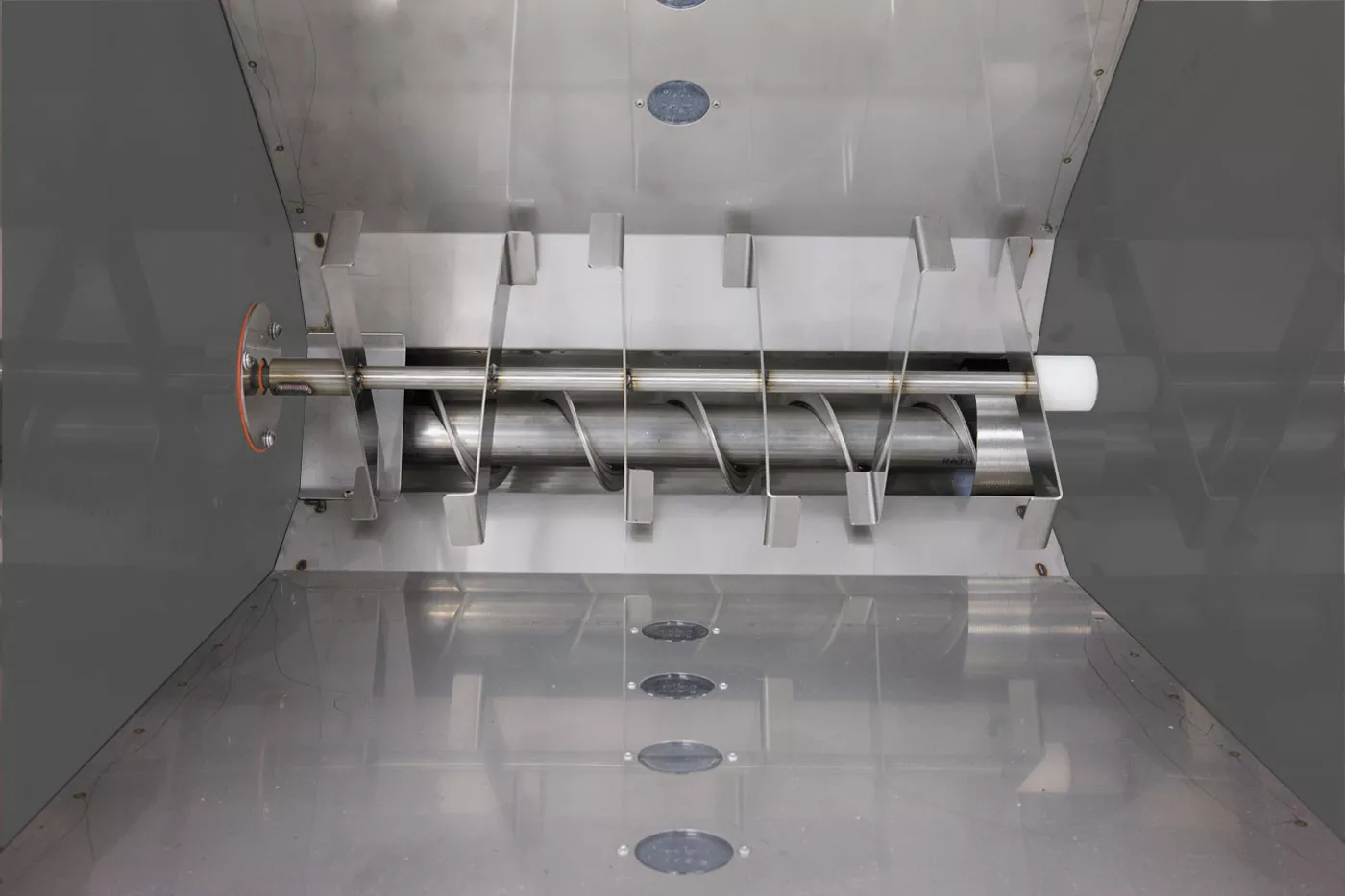

Dispense Devices

- Range of dispense valves for high throughput, minor components, poor flowing regrind, high volume pellets, and accurate low percentage dosing.

- Dose a range of percentages with maximum accuracy and control.

Real Time Data

- Blender measures every gram of every material.

- System monitors accuracy of total recipe and adjusts dosing.

Save Masterbatch & Additive up to 30%

- Precision dosing devices for accurate, repeatable control.

- Integrated software to optimize dosing accuracy in relation to whole blend.

Maximize on Regrind Usage

- Software and hardware controls regrind effectively.

- Options for maximizing regrind consumption and minimizing color usage.

Complete ROI – Within 6-9 Months

- Increased regrind levels, reduced masterbatch & additive settings can pay for the blender within 6-9 months.

- Maguire blender eliminates manual handling and reduce operation costs dramatically.

Vibration Management

- System is proven to manage accuracy in vibration environments.

- Unique controls and features to enhance even extreme environments.

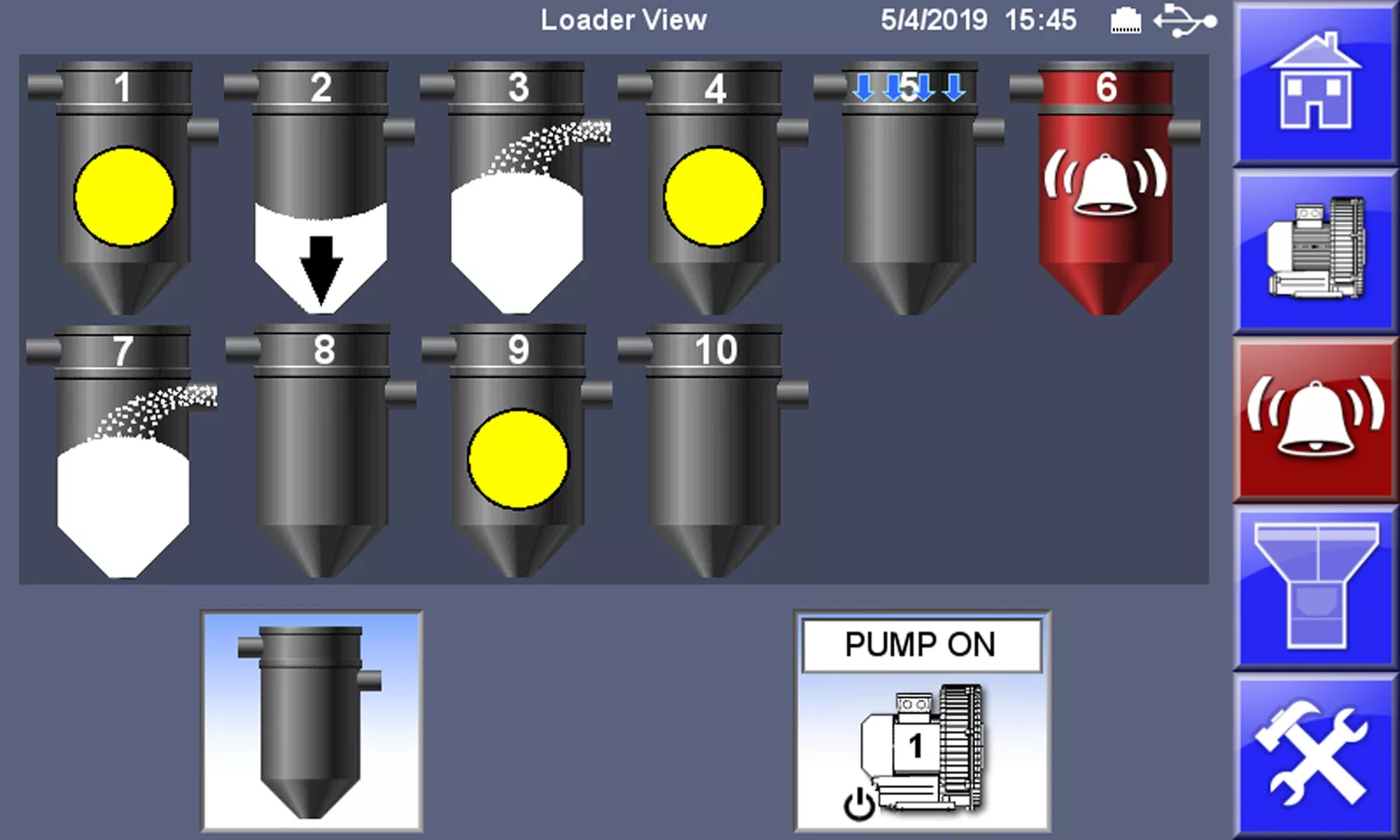

4088 Controller with FlexBus Lite

1. User Friendly HMI

Quick, simple to understand icons & graphics make set up quick & easy.

3. Quick & Easy Settings

See operation of blender, label materials & hoppers, view material percentage & type.

5. Quick Access to Popular Features & Functions

View material data, Access Recipe database, toggle Batch mode on and offline, Tag information and to increase throughput, operate in Fast mode.

7. Weigh Bin and Mix Chamber

Throughput, weight and dispensing component of each batch, plus status of material being mixed.

2. Alarms & User History

Exportable history as text files with date and time stamps.

4. Live Diagnostics

Materials usage and diagnostic reports for every cycle – printable to USB.

6. FlexBus Lite

The little brother of FlexBus – allows you to control up to 10 receivers and 1 vacuum pump.

8. System Parameters & Functions

Access to all features of blender to allow you to customize system to your process if required.

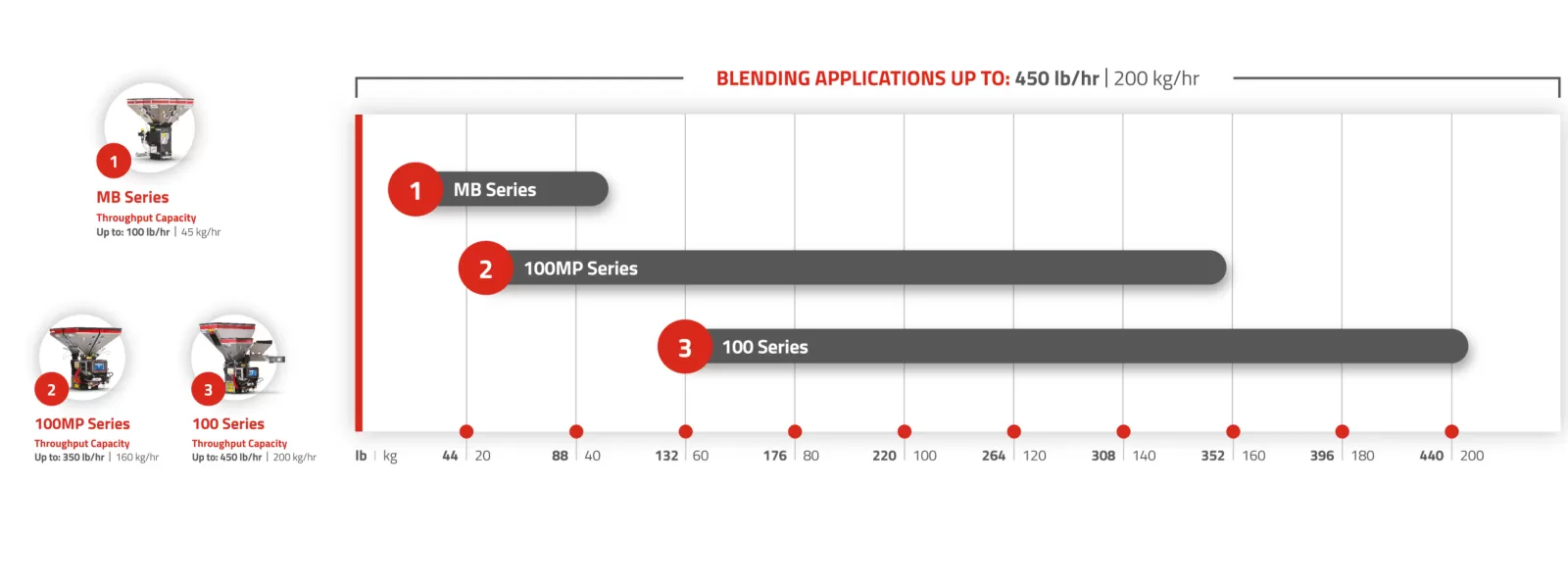

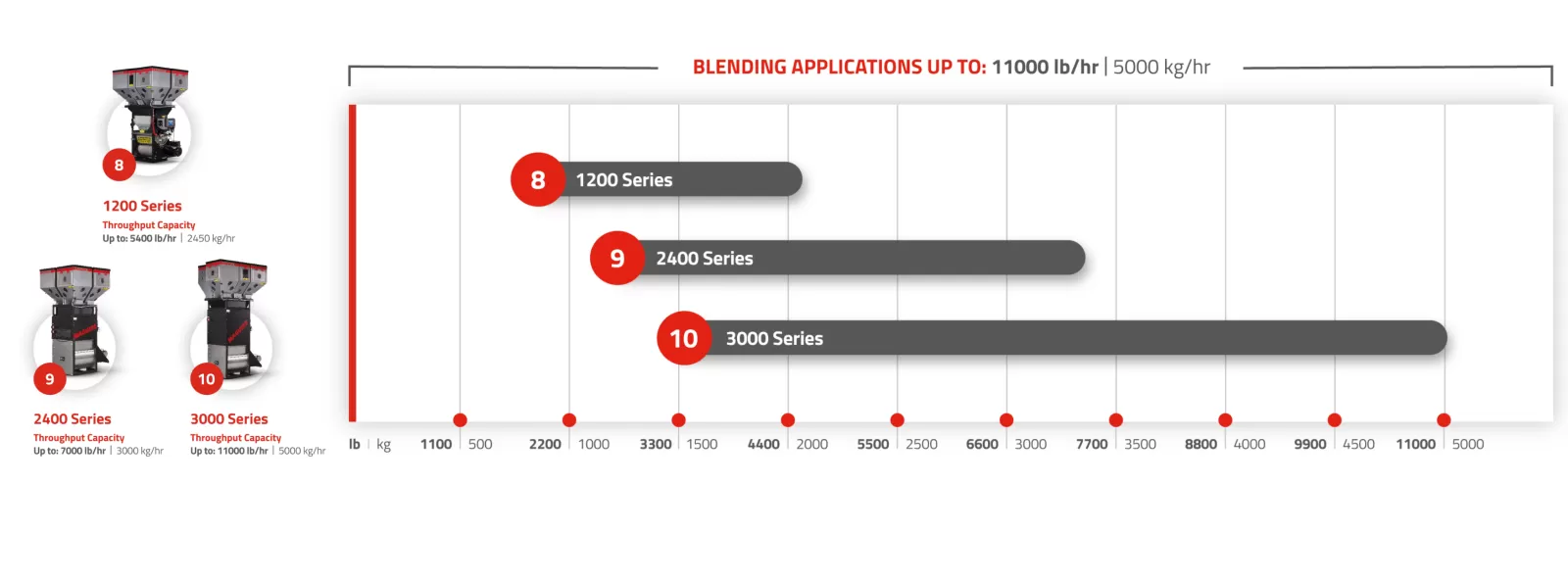

Capacity: 10 – 450 lb/h (5 – 200 kg/h)

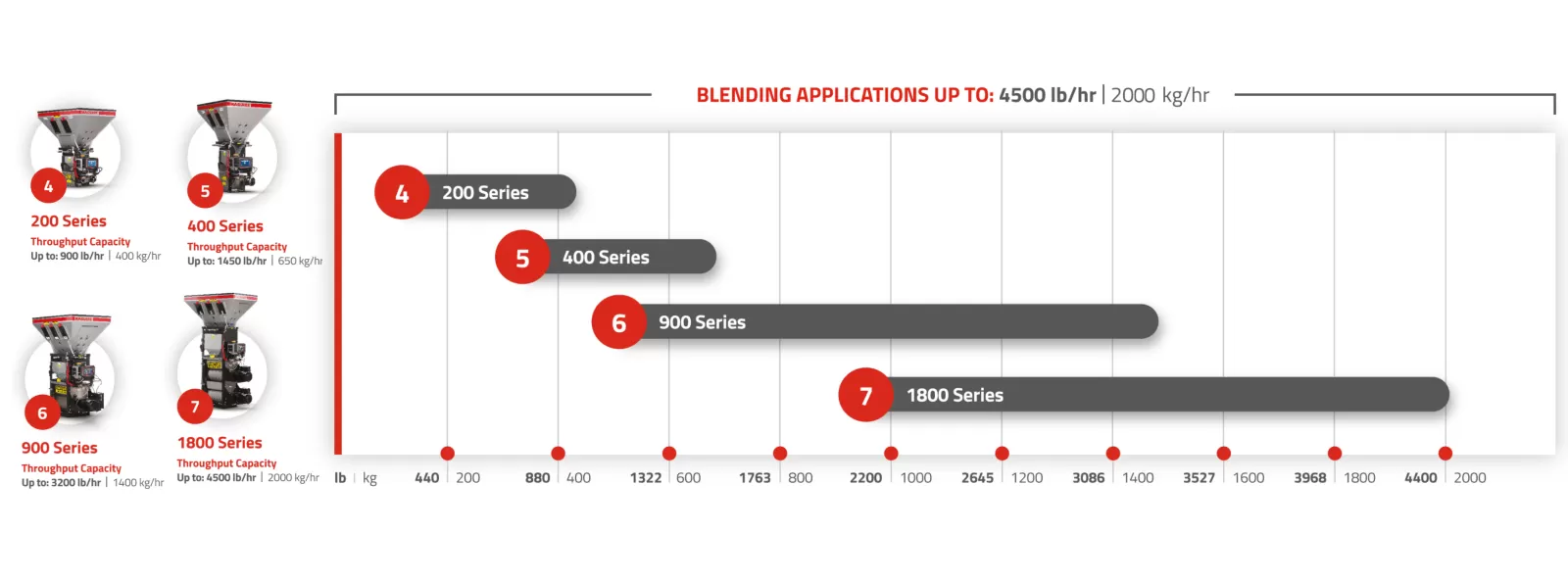

Capacity: 450 – 4,500 lb/h (200 – 2,000 kg/h)

Capacity: 1,500 – 11,000 lb/h (700 – 5,000 kg/h)

WSB Blender Options

| Dosing & Dispense Devices | ||

| Large Gram Target | Description | |

| 3″ x 6″ slide gates (76 mm x 152 mm) | Standard dispense devise for free-flowing materials |  |

| High volume pivot valve | Dispense valve for granules for high throughput applications |  |

| Corner Valve | For poor flowing regrind or high volume pellets |  |

| Wood Flour / Powder Feeder | For low bulk density powders |  |

| Medium Gram Target | Description | |

| 3″ x 6″ slide gates (51 mm x 152 mm) | Standard dispense devise for free-flowing materials |  |

| Pivot Valve | Vertical valve for removable hoppers |  |

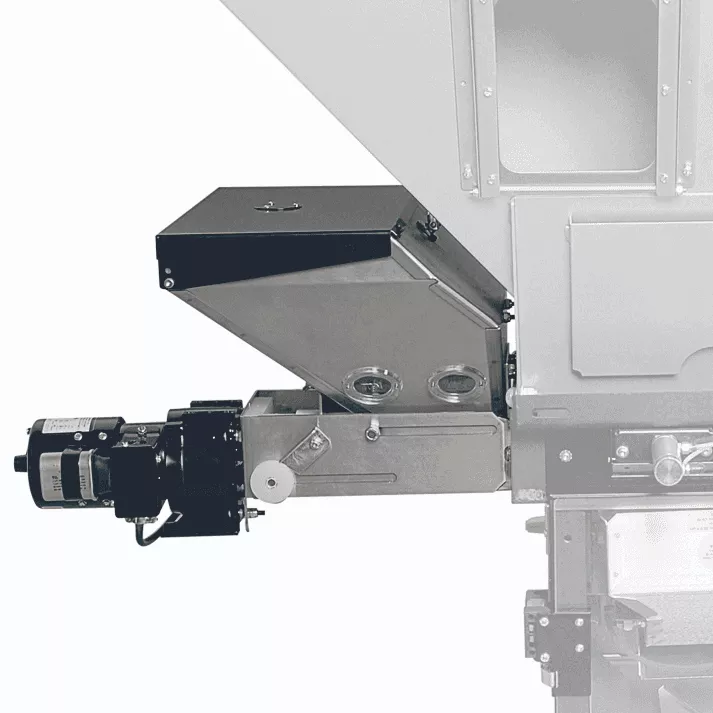

| Add-on Pellet Feeder | Add on feeder – 3 sizes – for dosing additive & masterbatch granules | |

| Add-on Powder Feeder | Add on feeder – 3 sizes – for dosing free flowing additive powders | |

| Low Gram Target | Description | |

| Carousel valve | Vertical valve for low dosing (10 gram or less) |  |

| Add-on pellet feeder | Add on feeder – 3 sizes – for dosing additive & masterbatch granules |  |

| Add-on powder feeder | Add on feeder – 3 sizes – for dosing free flowing additive powders |  |

| Add-on liquid color feeder | Liquid color pump integrates to blender to dispense liquid colors and additives |  |

| Build Options | Description | |

| Hopper Extensions | Range of hopper extension sizes for different models to increase storage capacity |  |

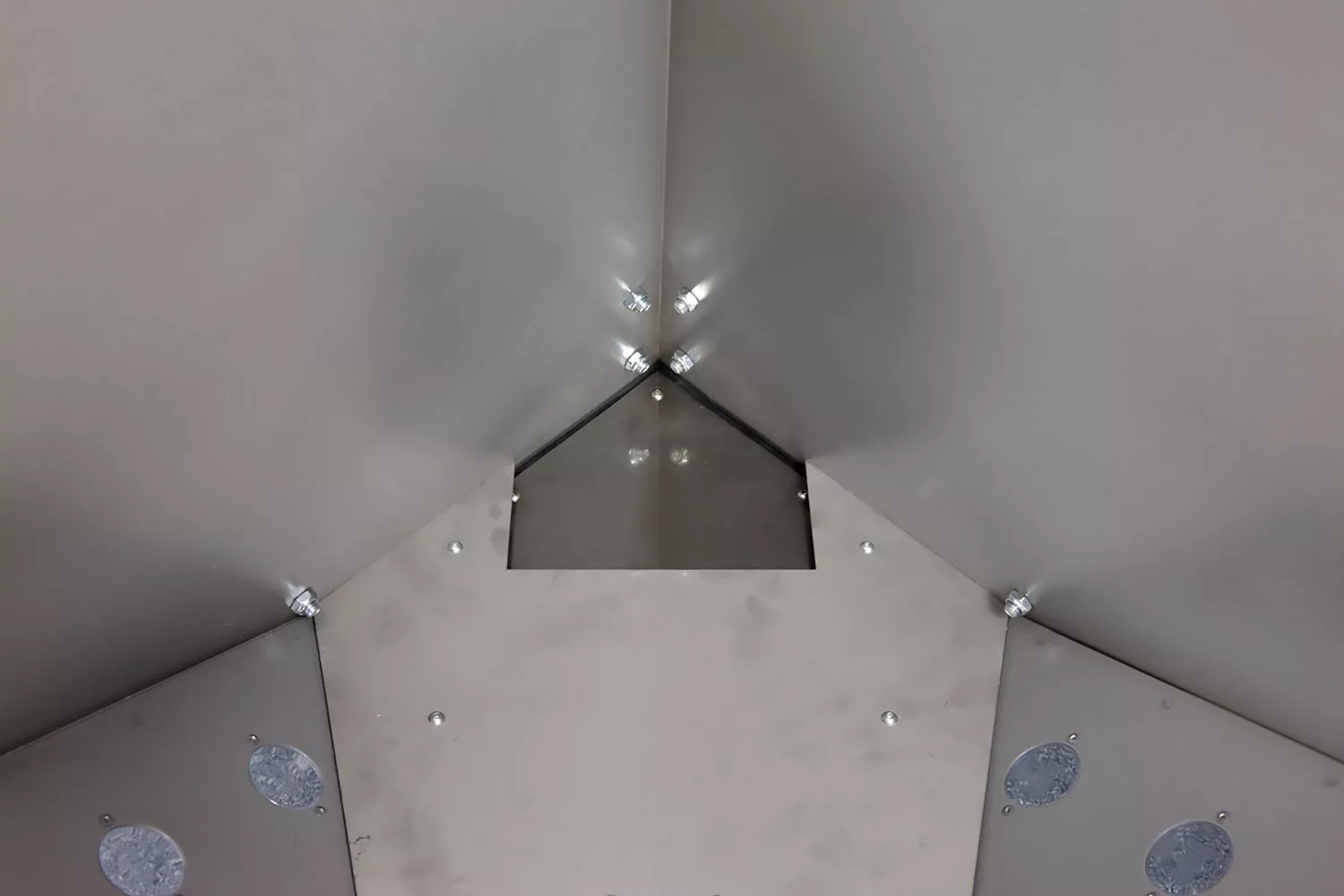

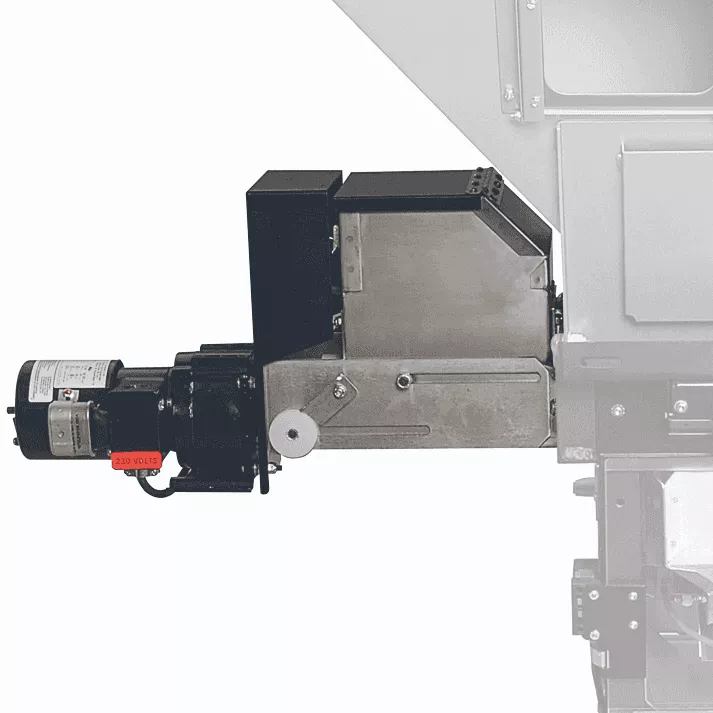

| Bridge Breakers | Range of bridge breakers to keep regrind / flake flow consistent |  |

| Low Level Hopper Alarm | 1 to 4 position low level hopper sensors to alert critically low materials in material hoppers |  |

| Removable Hoppers | For quick access & material changes |  |

| Removable Hopper Receiver Support Bracket | Support bracket to 2 removable hoppers, for easy hopper access and removal |  |

| Dual Level Sensor for mix Chamber | In lieu of single sensor on new WSB | |

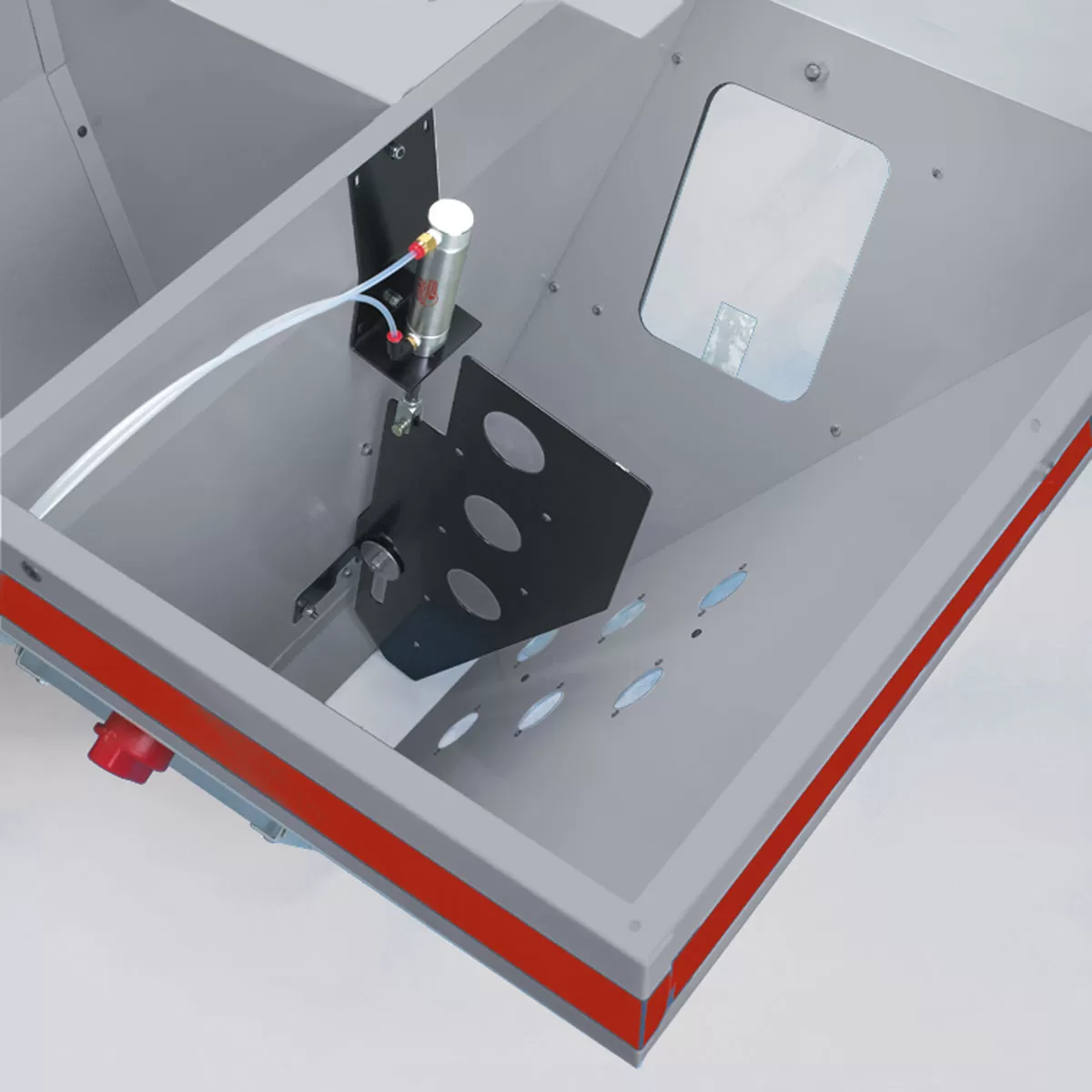

| Remote Red Sensor Mount Assembly | For mix chamber | |

| Self-draining Mix Chamber Assembly | For quick & easy clean out of mix chamber | |

| Hopper Material Drain Chute | For quick & easy clean out of material hoppers |  |

| High Temperature Configuration | 300°F / 150°C | |

| 4088 Touchscreen Controller Option | Allows full process visualization with simple graphics and easy HMI interface. Provides additional features over standard control including throughput and usage data & FlexBus Lite Materials Conveying Control, with all production parameters in one screen. |  |

| Controller Remote Cable Kit | Cable to locate the touchscreen remotely |  |

| Regrind Management Option | To automatically adjust regrind levels and manage regrind effectively. Available for all Maguire controller generations. | |

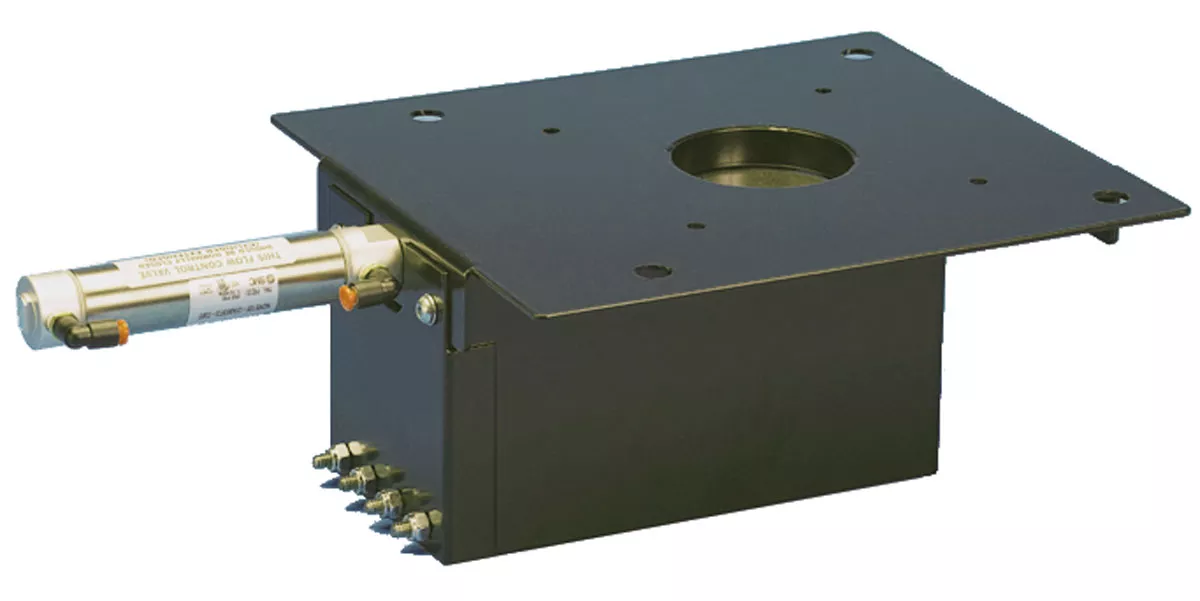

| Flow Control Butterfly Valve | Installed between blender and feed to machine to ensure material is held in mix chamber for good mixing prior to automatic release. |  |

| Flow Control Assembly | To ensure material is held in mix chamber for good mixing prior to automatic release into extruder (if mounted on machine throat) or material bin (if mounted on VTA stand) |  |

| VTA Blender Floor Stand | Blender mounted on floor stand to allow for easy access beside the machine. Quick material changes and cleaning. |  |

| Floor Stand Wheels | For highly mobile units |  |

| Additional Stand Probes | Probe for vacuum take-off stand |  |

| Clear-Vu Surge Hopper | Clear view of material loading |  |

| Stub Tubes | For use when WSB Blender is mounted on mezzanine floor |  |

| 4088 Touchscreen – FlexBus Lite | Description | |

| FlexBus Vacuum Pumps & Filters | Select Pump and then add FlexBus Control Module | |

| FlexBus Communication Cable | Pre made cable sets with quick connections for easy start-up | |

| FlexBus Retrofit Kit | Upgrade existing conveying system to run with FlexBus Lite |

There are no reviews yet.