Energy Efficient Drying

Energy Efficiency

- Energy to HEAT material from ambient temperature to target drying temperature is the same for all drying processes.

- Energy to DRY material is where the differences occur when comparing a Maguire LPD dryer to all types of Desiccant dryers.

- Side-by-side testing of the vacuum dryer and a desiccant dryer shows 70 – 80% reduced energy consumption.

Energy Saver Modes Built in as Standard

- Temperature Sense Control: Temperature is controlled efficiently with energy saver modes built in as standard.

- Heater and blower are automatically regulated to ensure that only the required amount of heat and air flow are used to bring material up to temperature.

Speed of Drying

- LPD dryers use vacuum as the main method to dry versus air desiccant.

- Typically, vacuum dryers dry 6 times faster than conventional desiccant dryers.

- This dramatically reduces energy used to dry material and translates to more production time.

Low Energy Components

- No regeneration process, no added energy used.

- Compared to Desiccant dryers, LPD dryers use only one smaller blower and heater sized based on smaller volumes and energy efficiency.

- Low maintenance: no scheduled maintenance requirements and no consumables.

Fast ROI

- LPD dryers quickly payback in the short term and continue to payback through energy reduction in the long term.

- Energy usage – one Desiccant day = one LPD week.

- Indirect benefits – increased productivity, reduced start-up scrap rates and reduced energy usage for the same time period.

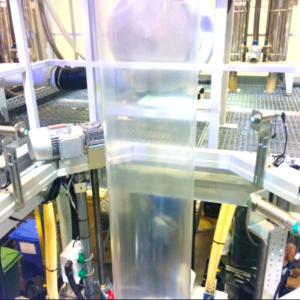

Patented 3-Step Drying Process

The Maguire LPD Vacuum dryer operates with 3 stainless steel canisters, mounted on a carousel that indexes step by step through the drying process.

Step 1 – Heating Phase

- The canister is filled with raw material.

- Material is heated from ambient to the required drying temperature.

- The time to get the material up to temperature is rapid – typically 20 – 30 minutes for most materials.

Step 2 – Vacuum Drying

- The canister indexes from the HEAT stage in (Position 1) to VACUUM stage in (Position 2).

- The vacuum canister is sealed and a high vacuum is applied to the hot material, dropping the boiling point of moisture to 133°F / 56°C.

- Vacuum is 56″Hg / 700 mmHg, typically for 20 to 30 minutes, depending on the material, initial / target moisture and required throughput.

- Vacuum only active usually 1-2 mins per cycle – minimal energy.

Step 3 – Material Feeding

- Material is now ready to use in production.

- The canister indexes to MATERIAL TAKE OFF (Position 3).

- A valve in the canister activates to allow material to feed to the material take off.

- Any material left in the canister by the end of the drying cycle time simply rotates back to HEAT stage, (Position 1) and fresh material supplied from the VACUUM stage (Position 2), eliminating any chance of moisture re-absorption or material cooling.

How a Low Energy LPD Dryer works:

Experience Simple Drying

|

User-Friendly Control

|

|

|

Simple Operation

|

|

Drying Parameters

|

|

Drying Control

|

|

Quick Material Changes

|

LPD Dryers at a Glance

1. Low Energy Dryer

Compared to desiccant dryers, LPD dryers use only one smaller blower and heater based on smaller volumes and energy efficiency. No regeneration process, no added energy used.

3. User-Friendly Control

Simply set drying temperature, drying cycle time and system starts.

5. Quick Material Changes

The LPD dryer dries in batches. A material or color change can be made while drying previous materials. No downtime. No interruption of drying process.

2. Fast Return on Investment

LPD Dryers quickly provide return on investment in the short term and continue to payback through energy reduction in the long term.

4. Drying Parameters

Display indicates temperature and elasped cycle time. View actual vacuum level and temperature in process.

6. Speed of Drying

LPD dryers use vacuum as the main method to dryer, versus air desiccant. This is typically 6 times faster than conventional desiccant dryers.

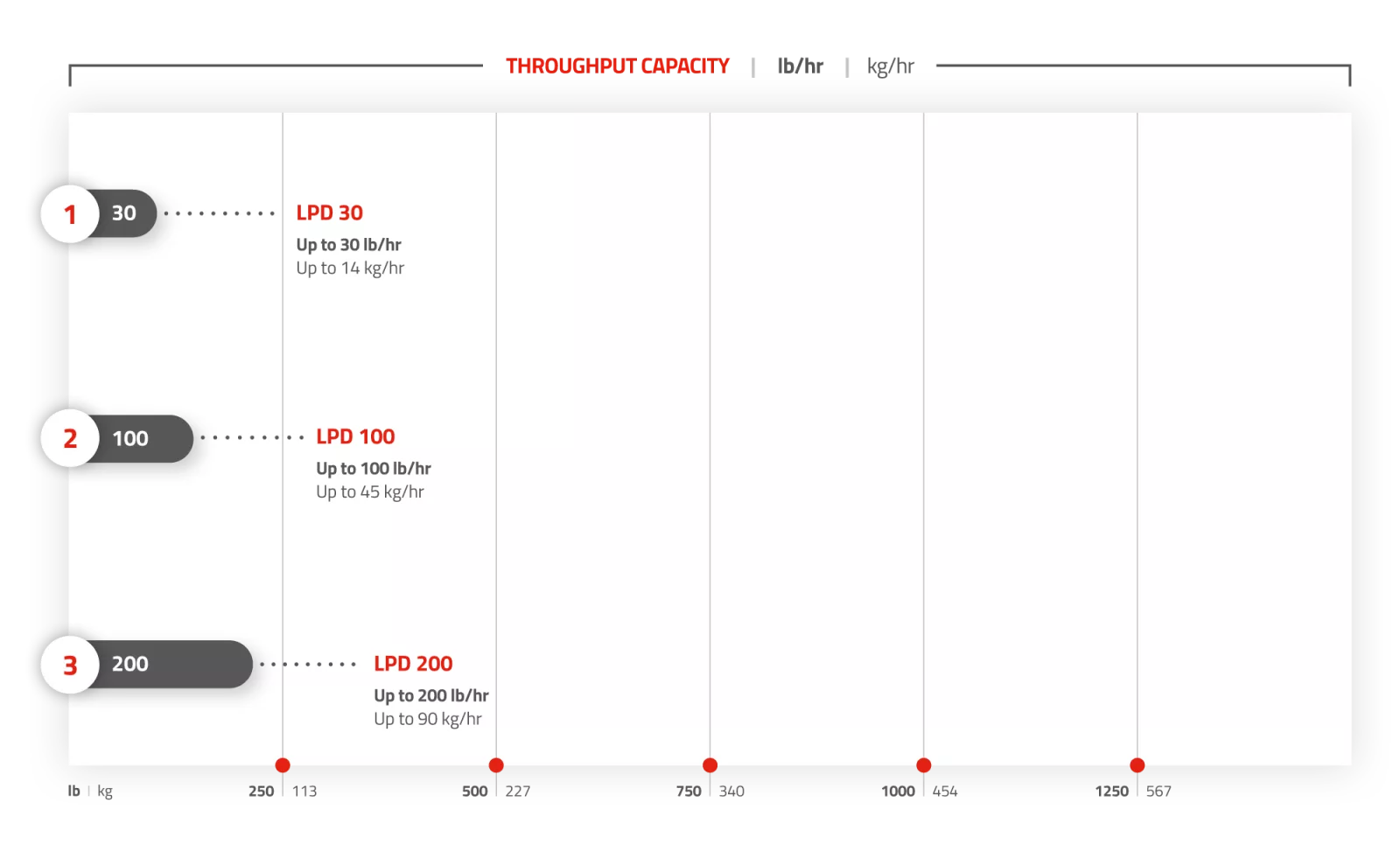

LPD Range

LPD Options

| Option | Model | Description |

| Clear-Vu Vacuum Receiver | LPD 30, LPD 100, LPD 200 | Flapper valve, for high heat applications. |

| Aluminium Material Conveying Flexible Tube | LPD 30, LPD 100, LPD 200 | LPD conveying package. |

| Dual Convey Kit | LPD 30, LPD 100, LPD 200 | To allow connection to 2 machine receivers. |

| Gravity Dispense Kit | LPD 30, LPD 100, LPD 200 | For vertical feeds. Gravity discharge feeds material directly into process machine. For mezzanine / elevated installations. |

| Membrane Vacuum Purge Kit | LPD 30, LPD 100, LPD 200 | Recommended for highly hydroscopic materials. |

| Spare Canisters | LPD 30, LPD 100, LPD 200 | For quick material loading and faster process turn around. |

| Throat Mount for Canister | LPD 30, LPD 100, LPD 200 | For mounting on the throat. |

| Spare Controller | LPD 30, LPD 100, LPD 200 | To allow secondary remote controller to dryer for remote access and control. |

| Air Filter for High Temperature Applications | LPD 30, LPD 100, LPD 200 | High heat option. |

There are no reviews yet.