ULTRA Low Energy Usage – How

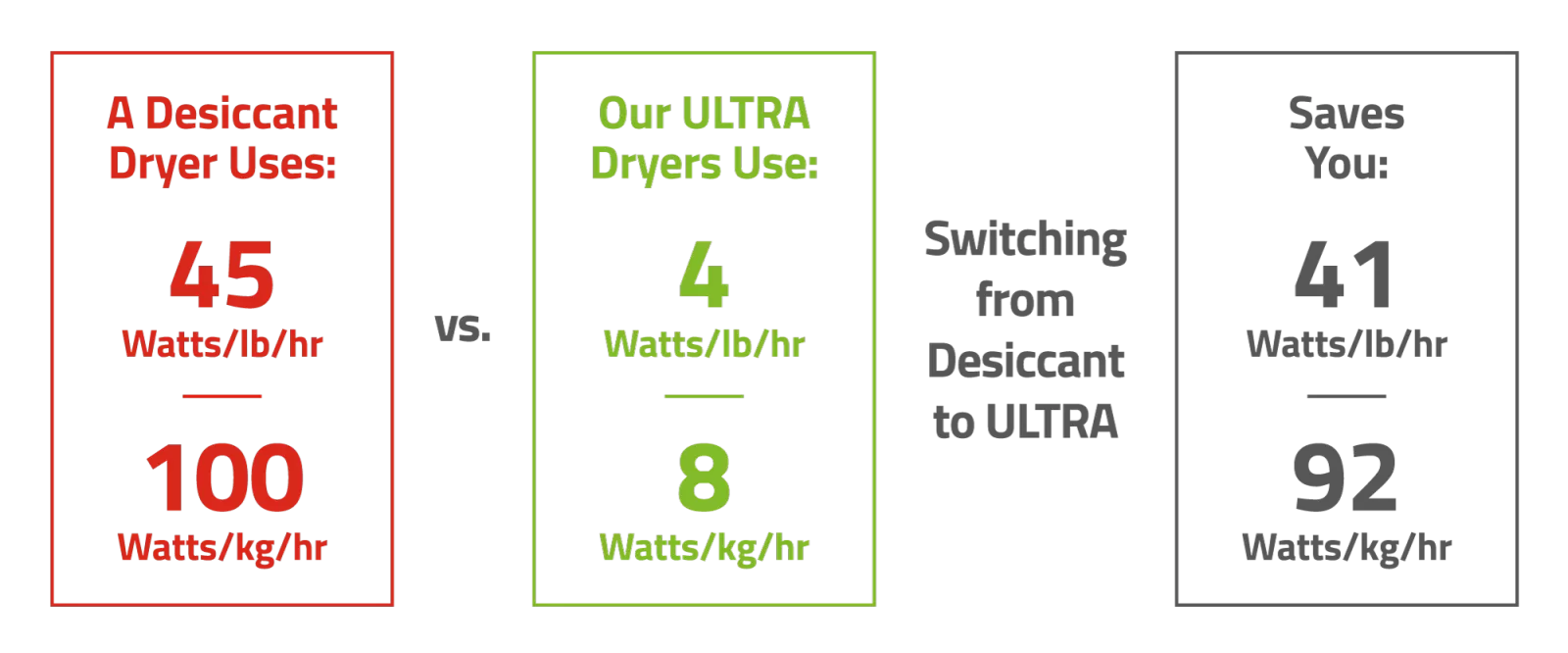

ULTRA Energy – Efficiency Comparison

- kW energy to HEAT raw material from ambient to required drying temperature is the same for all drying processes.

- kW energy to DRY raw material is where the difference occurs, comparing ULTRA dryers to all Desiccant dryers.

ULTRA Low Energy – Operating Cost Savings

- A process running at 220lb/h (100kg/h) can typically see a kW difference of 41 Watts/lb (92 Watts/kg) with ULTRA dryers versus generic desiccant dryer.

- This saves $6,500 annually at an example rate of 220lb/h (100kg/h) – whilst doing the exact same job.

- ULTRA delivers savings year on year for its full life cycle.

ULTRA Low Energy – Dynamic Software

- Temperature Sense Control – temperature is controlled efficiently with energy saver as standard.

- Heater and air flow are automatically regulated to ensure only the required amount of heat and air flow are used to bring material up to temperature.

ULTRA Quick Drying

- ULTRA dryers place materials under vacuum to dry rapidly, versus long exposure to desiccant hot dry air flow.

- Normally, ULTRA dries material 6 times faster than conventional desiccant dryers.

- ULTRA fast drying time provides quicker start-ups.

ULTRA Low Energy Components

- No regeneration process, no added energy used.

- ULTRA uses only one smaller blower and heater sized for smaller volumes and faster drying times.

- Compact heating hopper – less material in process, less energy used, easier cleaning.

- Minimal maintenance – no scheduled maintenance requirements and no consumables.

ULTRA Live Throughput Monitoring

- Load cells monitor the vacuum chamber and retention hopper and provide live materials usage data.

- Data allows the drying rate to efficiently follow and adjust according to the dryer consumption rate.

- ULTRA live data makes for ULTRA efficient drying.

ULTRA Fast Return on Investment

- ULTRA dryers quickly pay-back in the short term and continue to provide energy reduction cost savings in the long term.

- Energy usage – one Desiccant day = one ULTRA week.

- Indirect benefits – increased productivity, reduced start-up scrap rates and reduced energy usage for the same time period.

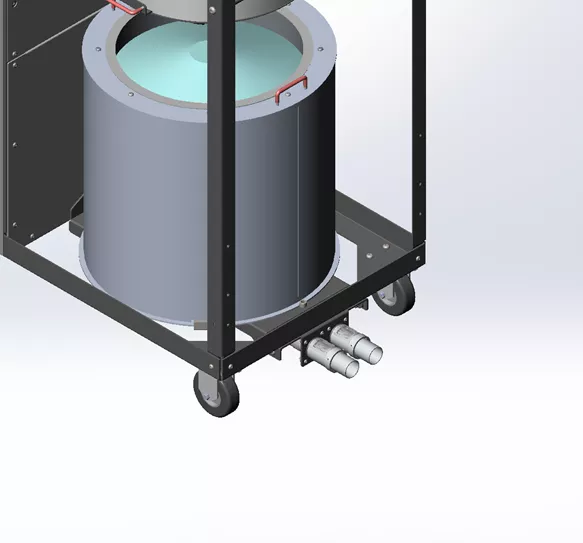

ULTRA Drying Process – How

ULTRA low energy dryers operate in a three-step process:

1 – Heating Hopper

- HEAT – The heating hopper is loaded with raw material and heated to the normal drying temperature for a short period of time. Examples:

- For ABS typical HEAT time is 15 to 30 minutes at 176 °F / 80 °C.

- For PET typical HEAT time is 40 to 60 minutes at a drying temperature of 338 °F / 170 °C.

2 – Vacuum Chamber

- Hot material is released into the vacuum chamber, the amount monitored by load cells and adjusted automatically.

- DRY – The vacuum chamber is sealed and a high vacuum is applied to the hot material, dropping the boiling point of moisture to 133°F / 56°C.

- Vacuum is 56″Hg / 700 mmHg, typically for 20 to 30 minutes, depending on the material, initial / target moisture and required throughput.

- Vacuum only active usually 1-2 mins per cycle – minimal energy.

3 – Retention Hopper

- The retention hopper is mounted on load cells monitoring materials usage live.

- Live usage data indicates when to release material from the vacuum chamber, adjusting material in process automatically.

- Optional dry air purge – only for very hygroscopic materials.

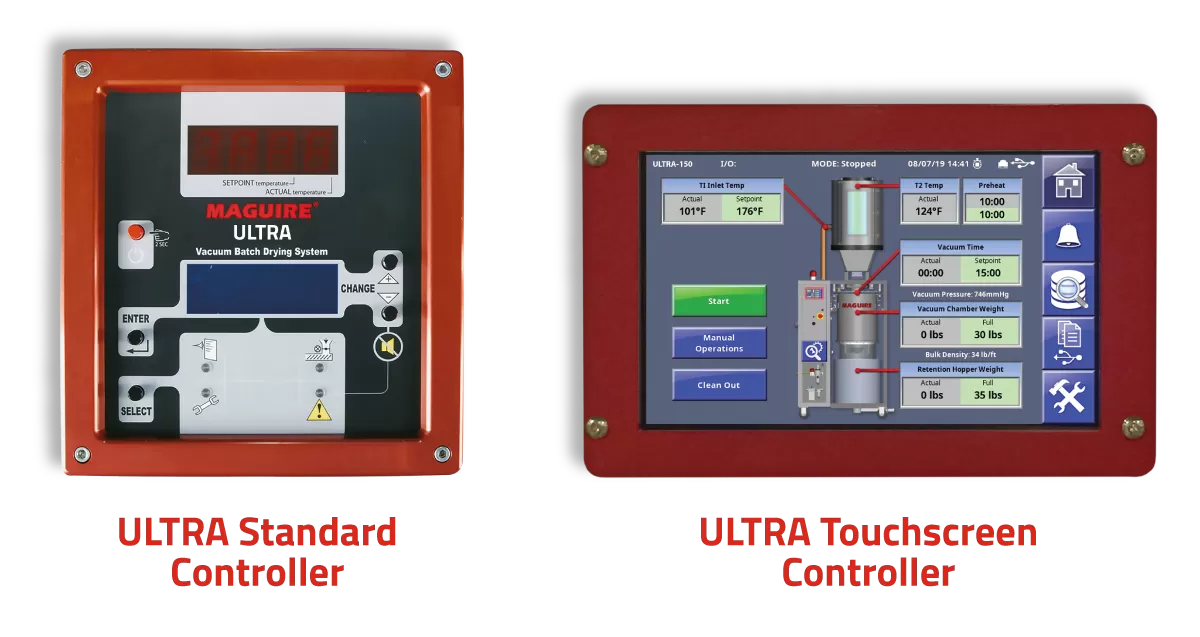

ULTRA Intuitive Controls – How

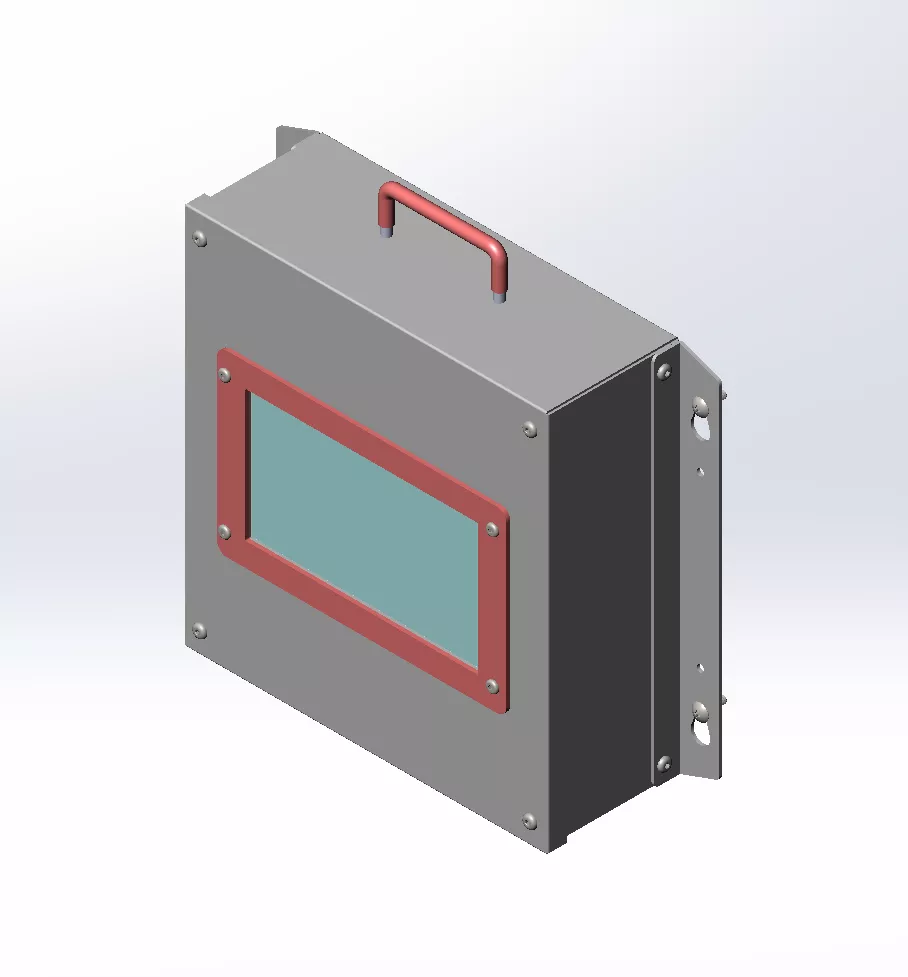

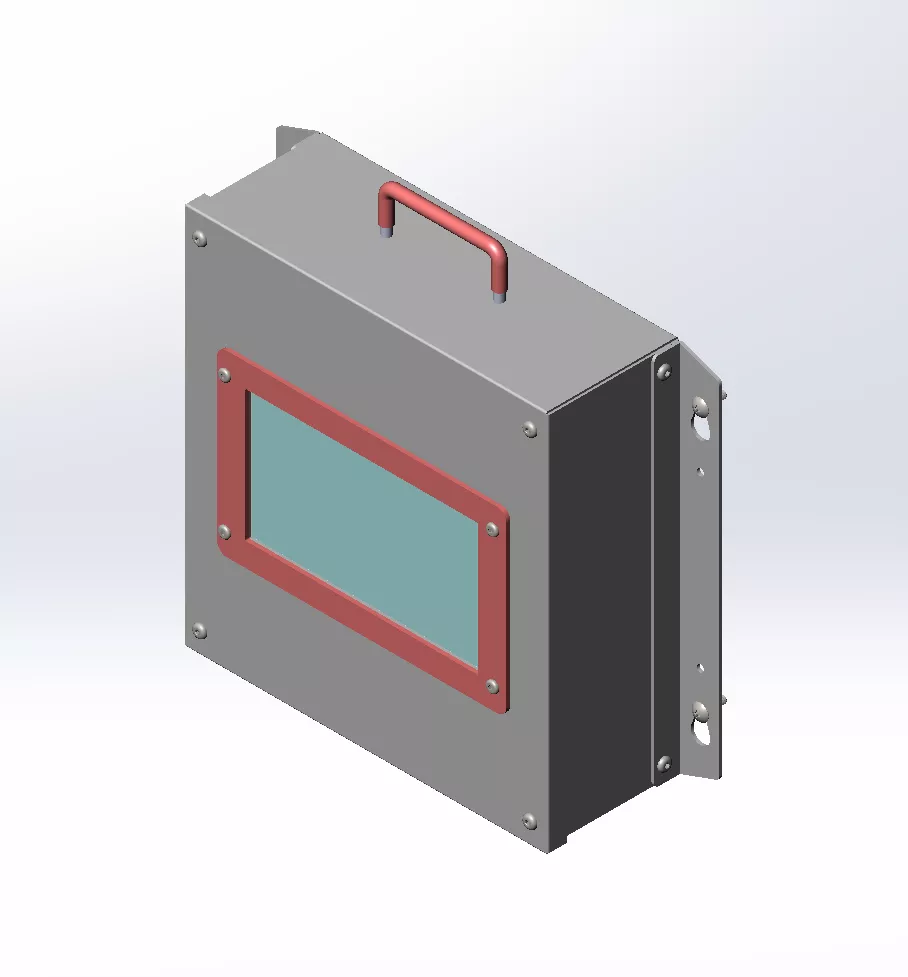

ULTRA Control

The ULTRA Dryer has a choice of two control types – standard or touchscreen.

Standard / Touchscreen

- Easy set up and operation of dryer.

- Monitoring and logging of multiple alarm conditions.

- Simple export function & software update.

Touchscreen

- Easy operator visualization in one screen.

- Integrated FlexBus Lite materials conveying control.

ULTRA Control – Multiple Features and Functions

![]()

Auto Stop Feature – Simple cleaning / Shutdown

Load cell data allows an Auto Stop time to be set. The dryer finishes at the time set with no material left inside – this allows quick cleaning and startup of new materials.

![]()

Dynamic Drying Feature – Efficient Drying

Load cell data automatically adjusts drying rate to process rate – only dries what’s required, minimizing kW per lb / kilo.

![]()

Auto Start Feature – Simplify Startup

Another standard feature that allows material to be scheduled and ready without operator intervention.

ULTRA Sustainability – How

ULTRA Green – Reduced Environmental Impact

ULTRA’s unique design and method of drying by vacuum means the Maguire ULTRA dryer dramatically reduces energy usage.

This energy reduction significantly improves sustainability by reducing a processors Global Warming Potential (GWP).

On a process running 220 lbs/hr (100 kg/hr) an ULTRA dryer provides savings of 54,120 kW a year*. Year on year.

Carbon Sequestered By*

Carbon Footprint Savings – Example

| ULTRA Dryer | New Desiccant Dryer | |

| Hourly kW Usage to DRY material | 4 Watts/lb/hr | 45 Watts/lb/hr |

| Hourly kW Usage to HEAT material | 10 Watts/lb/hr | 10 Watts/lb/hr |

| Annual kW Usage | 18,480 kW | 72, 600 kW |

| Annual Difference to ULTRA | 54,120 kW saved | |

| Carbon Savings** kg CO2e – Annual | 13,833 kgCO2e | |

| Carbon Savings** kg CO2e – Dryer lifetime (15ys) | 221,329 kgCO2e |

*Energy savings vs. old dryer made on recent comparisons. **Carbon data source – Carbon Trust – Industrial energy

ULTRA Smart Controls

1. Live Temperature

Actual temperature inside heating hopper shown.

3. Live Weight in Vacuum Chamber

Weight of material in vacuum chamber.

5. Material Pre-Set Selection Library

7. Auto Stop

Dryer finishes at time set with no material left inside.

2. Live Vacuum Status

Shows remaining vacuum time versus Setpoint.

4. Heavily Insulated

Maintains DRY material before going to process.

6. Actual Amount of Material

Weight of material in the Retention Hopper.

8. Air Pressure Indication

Will show in red service box if any issue detected.

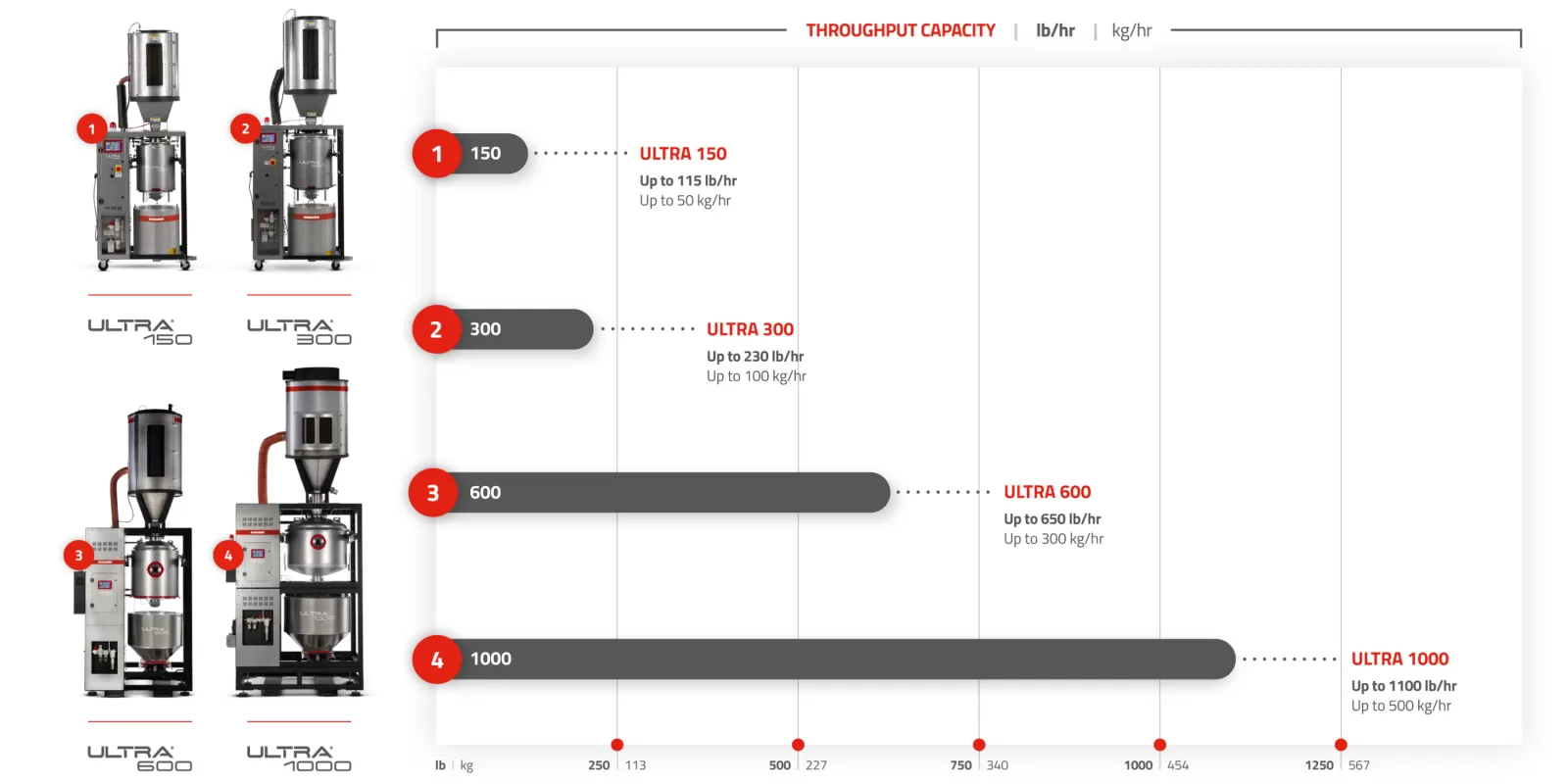

ULTRA Dryer Range

ULTRA Options

| Option | Model | Description | |

| Heating Hopper Drain Chute | ULTRA 150, ULTRA 300 | For rapid and easy draining of raw materials for fast process turnaround |  |

| Vacuum Take-Off Assembly | ULTRA 150, ULTRA 300 | 2” (51 mm) dia. dispense tube feeds material directly into process machine. 2 1/2” (63.5 mm) dia. dispense tube feeds material directly into process machine |

|

| 3-Phase Monitoring Kit | ULTRA 150, ULTRA 300 | Prevents an ULTRA dryer from running if 3-phase rotation is backwards. Recommended for mobile dryers. | |

| Heating Hopper Extension | ULTRA 150, ULTRA 300 | To increase heat residence time, or for running at higher throughputs to ensure normal heating residence time. Recommended for specialized materials i.e. PA, PET. |  |

| VFD 240V | ULTRA 150 | To reduce further energy consumption at lower process throughputs. | |

| VFD 400/480V | ULTRA 150 | To reduce further energy consumption at lower process throughputs. | |

| VFD 400/480V | ULTRA 300 | To reduce further energy consumption at lower process throughputs. | |

| Multi-point Convey Kit | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | To allow connection to 2 machine receivers. |  |

| Gravity Feed Kit | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | For vertical feeds. Gravity discharge meeds material directly into process machine. For mezzanine/elevated installations. | |

| Touchscreen Option | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | Allows full process visualisation with simple graphics and easy HMI interface – provides additional features over standard control including throughput and usage data & FlexBus Lite Materials Conveying Control, All production parameters in one screen. |

| Remote Controller | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | Relocates the ULTRA controller to a remote location for ease of access and control on main process. |  |

| Remote HMI | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | Cable to locate the touchscreen remotely, standard cable length 50 ft (15 m). |  |

| Secondary Remote | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | To allow secondary touchscreen remote interface to dryer for remote access and control. | |

| Base Support Frame | ULTRA 1000 | When installed directly on floor/non mezzanine platform installations. | |

| Membrane Dry Air Purge Option | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | Positive dry air low pressure blanket to prevent moisture re-absorption in vacuum chamber and retention hopper. Recommended for highly hygroscopic materials. | |

| Vacuum Generator Filter | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | Filter to prevent dust from entering process check valve in the event of high dust applications – for example regrind applications. | |

| ULTRA FlexBus Lite Option | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | FlexBus Lite material conveying pre-wiring. Simple connect dryer & machine or small group of machines | |

| LowPro Materials Conveying Receiver | ULTRA 150, ULTRA 300, ULTRA 600, ULTRA 1000 | 7 lb (13 L) materials receiver, easy integration to ULTRA heating hopper, ideal for limited height installations. |  |

There are no reviews yet.